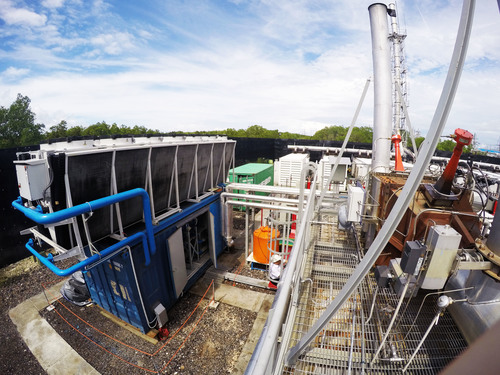

Heat Recovery Solution for Two Landfill Gas Engines in the UK

One ORC powered by two landfill gas engines In the United Kingdom, operating landfill gas engine exhausts are utilized as the heat source to run a Clean Cycle® heat recovery unit. In this case, two small engine exhausts are combined to give 1 MW thermal to power one organic rankine cycle unit producing 140 kW electric gross power. The ORC Clean Cycle® unit was packaged in a modified shipping container and the container doubled as the mounting frame for the overhead condenser. This Clean Cycle has run for greater than 38,000 operating hours.